IGI uses suppliers from large dairies that are subject to a strict inspection regime. Milk is received at the plant through four lines. The IGI contains free genealogical information, submitted from various sources including names. GMR Varalakshmi Foundation (GMRVF), is the Corporate Social Responsibility arm of GMR Group.“Until IGI’s investment in the dairy, domestic milk in Egypt was sold by street vendors fresh from the pail and would need boiling at home before use.”Buy IGI Diamonds online Up to 70 price advantage Certified by IGI-GIA-HRD Free shipping on all orders Buy straight from the source at wholesale.The International Genealogical Index (IGI) is a database of genealogical records, compiled from several sources, and maintained by The Church of Jesus Christ of Latter-day Saints.Originally created in 1969, the index was intended to help track the performance of temple ordinances for the deceased. It has a plethora of history and monuments that one needs to know and visit. Delhi the capital city of India, located at the heart of the country is a massive metropolitan area with a diversified culture and tradition.

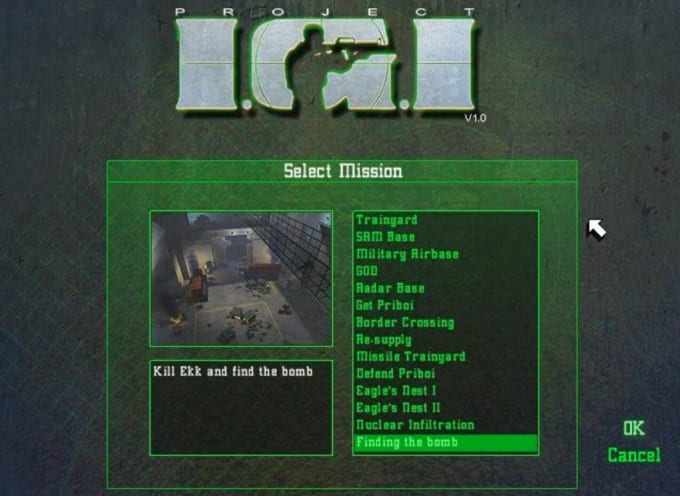

A GEA Finnah UHT system is then available to process the milk or it can be passed to the yoghurt department. Italian GEA subsidiary Niro Soavi supplied equipment for homogenisation.IGI: Origins, the prequel to 2000s Project I.G.I, is a stealth shooter, high octane thrill ride of a video game currently in development by Antimatter.From here, processed milk is passed to a tank store with a total capacity of 336,000l. The processing line uses a Tetra Alfast installation from TetraPak to standardise fat content.

Blown bottles arrive at the production line sealed and are opened with a knife blade. After mixing with flavourings, finished yoghurts pass through a GEA Finnah forming, filling and sealing machine capable of operating at a maximum rate of 18,000 cups per hour.Beyti produces a range of blowformed HDPE in 250ml, 1,000ml and 1,500ml sizes, using fresh granulate from Solvay. Hansen supplies Direct Vat Set cultures to produce a range of different yoghurt styles. A discrete Scanima unit dissolves dry additives including stabilisers and flavourings prior to their use in the yoghurt milk. YOGHURT PROCESSINGAs well as own-brand products the plant also has a Goavec-designed facility producing Yoplait stirred and set yoghurts under licence.

Palletising is carried out manually in the warehouse where a Franpack shrink wrapper is used to prepare the full pallets for transport.In June 2007 Beyti started to change over to aseptic carton packs from SIG Combibloc with the new screw cap combiSwift. The coded bottles are checked using a Krones Checkmate and any that fail to meet IGI’s standards are discarded before the batch passes on to the warehouse.Secondary packaging is then carried out using equipment supplied by Kettner, Geysel and Krones. After being filled the bottles are passed along a Krones conveyor and stamped with a UV code for internal tracking.

‘Beyti’-brand nectars will now be offered in combiblocSlimline 1,000ml and the handy single-serve combiblocMini 250ml carton pack with drinking straw.With the installation of the filling machines CFA 310-32 (500ml and 1,000ml) and CFA 112-32 (125 to 250ml), Beyti has opted for maximum efficiency and flexibility in its packaging operation.The superior opening behaviour of combiSwift is based on a new technology. The company is now also turning its hand to fruit nectars. With an internal diameter of 18mm, combiSwift is a handy, flat opening system for liquid dairy products, and for fruit juices and other non-carbonated beverages.“In June 2007 Beyti started to change over to aseptic carton packs from SIG Combibloc with the new screw cap combiSwift.”Until now, Beyti has been manufacturing solely for the milk and dairy products sectors using only HDPE bottles.

Igi Plus A Screw

CombiSwift is fitted with a three-way tamper-evident guarantee, which indicates at a glance whether the package still has its original seal. CombiSwift consists of a flange with integrated cutting ring, plus a screw cap. Before the unprocessed cardboard is coated with aluminium and polyethylene, holes of the exact size are punched in the carton at SIG Combibloc’s packaging material plants.After the product has been filled into the carton by the manufacturer, the combiSwift opening system is applied over the pre-coated hole.

GEA worked closely with UK-based Shepherd Design on the architectural and building services aspects of the project.Of the $26.2m contract, $10m was spent on processing, $9m on packaging and the remaining $7m split between utilities and construction management. The firm also took design responsibility for the civil, structural and architectural elements of the project, all utility projects and full process and packaging design. The site chosen for the dairy was about 70km from Alexandria and 150km from Cairo on the main highway linking the cities, is deep in the desert but had good access to water from the Alexandria Canal.GEA was given full responsibility to manage the project. NOUBARIA DAIRY CONSTRUCTIONIGI chose GEA Process Technologies, Ireland, (a division of Germany’s GEA Tuchenhagen) to lead the project under a $26.2m turnkey deal.

0 kommentar(er)

0 kommentar(er)